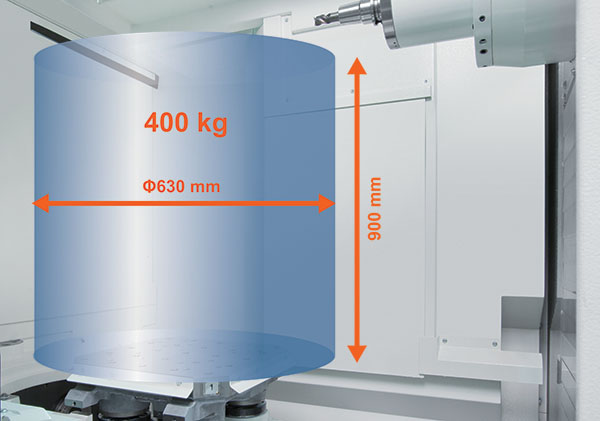

Machining area for large, heavy workpieces

Horizontal Machining Centers

Designed to provide unsurpassed performance, productivity and reliability

Increased cutting performance thanks to high-rigidity bed and column

The increased number of available spindle specifications provides efficient machining for a wide variety of workpiece material

Longer Y-axis stroke and larger maximum tool diameter for increased productivity

Higher Productivity

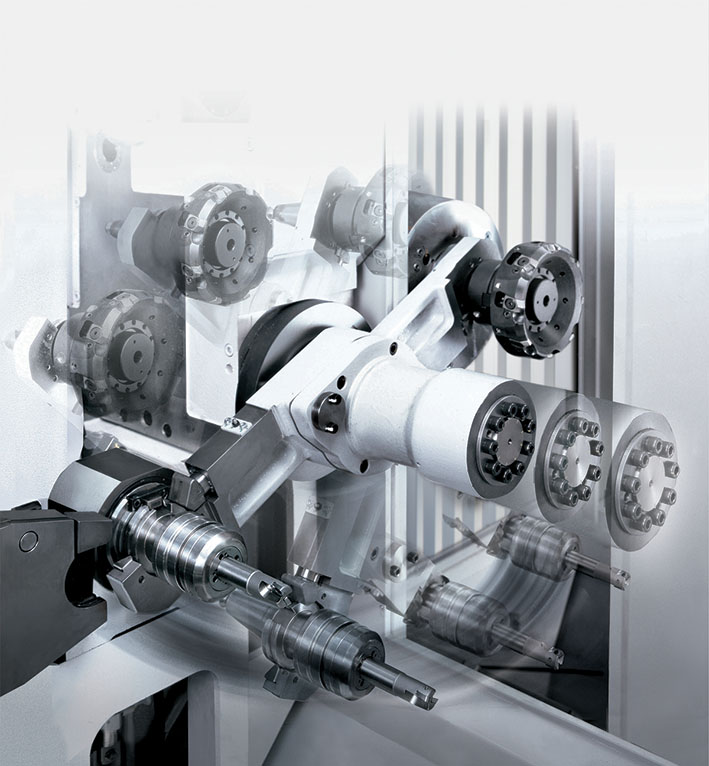

High-speed ATC

The cam-driven tool changer ensures reliable high-speed tool change cycles

Design Features for Unsurpassed Ease of Operation

Large Window

The large front window allows the operator to easily monitor workpiece machining.

Swiveling Operation Panel

Tool inspection and the machine current position can be conveniently checked by the movable CNC operation panel.

Maintenance Area

Items requiring frequent access for machine operation, such as hydraulic and air pressure inlets, lubrication reservoirs and others are conveniently arranged.

Loading / Unloading Station

The loading / unloading station for the 2-pallet changer provides excellent accessibility to the workpiece. Additionally, 90° positioning (4 positions) is available for convenient workpiece loading and unloading.

2 Pallet Changer Door

The wide door opening at the front of the machine provides excellent accessibility to the pallet at the setup station for convenient loading / unloading of large, heavy workpieces.

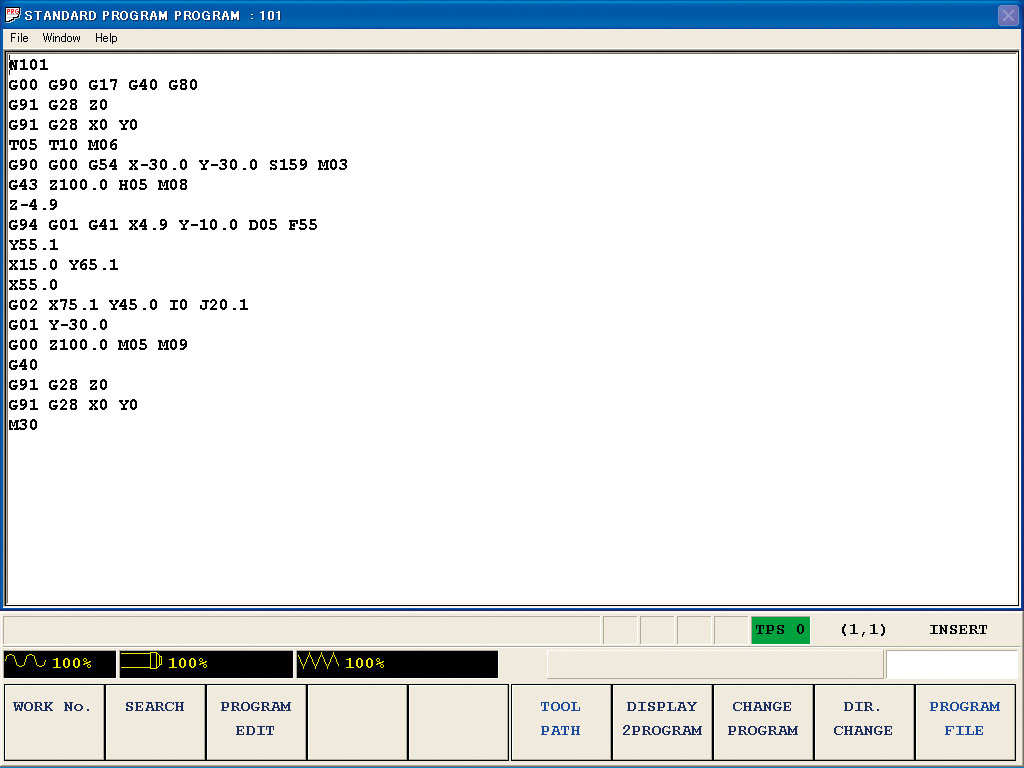

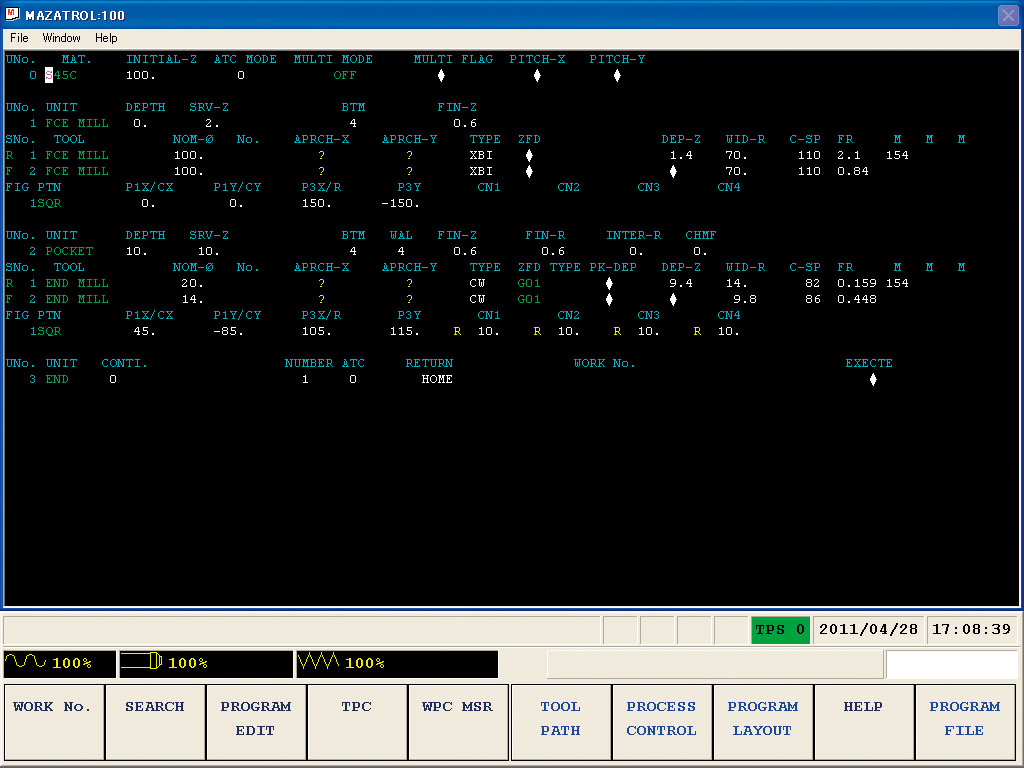

Ease of Programming

Ability to use both conversational programming and EIA / ISO program formats – standard equipment

Multiple surface processing can be performed by conversational programming or EIA / ISO programs that are prepared by CAM systems

EIA / ISO program display